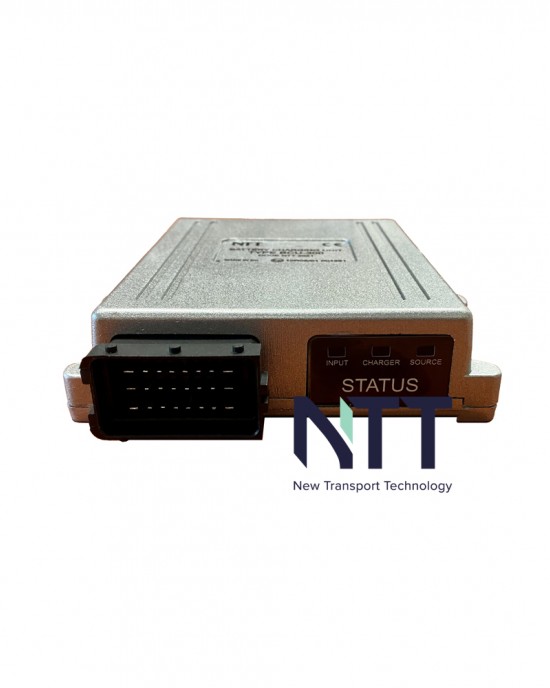

Battery charge control unit BCU-300

- Stock status: In Stock

- Model: BCU-300

- Shipping Weight: 0.30kg

- Dimensions: 20.00cm x 20.00cm x 3.00cm

- SKU: BCU-300

- ISBN: BCU-300

- MPN: BCU-300

Available Options

Our clients often encounter significant issues when operating refrigerated trailers:

1. Rapid refrigeration unit battery discharge: Increased security demands for semi-trailer protection (alarms, additional sensors, trackers, electronic door locks, etc.) lead to higher power consumption of the refrigeration unit's battery.

2. Untimely activation of the unit: Delays in starting the unit can result in temperature fluctuations inside the refrigerated trailer, potentially leading to damage or product loss.

3. Frequent battery replacement: Regular battery replacements become a costly and inefficient procedure, accompanied by downtime for the refrigerated trailer.

4. Driver dissatisfaction: Dissatisfied drivers can reduce the productivity and safety of your transportation logistics, directly impacting the efficiency of the entire supply chain.

5. Increased fuel consumption: Improper functioning of refrigerated trailers can cause excessive fuel consumption, raising operational costs and reducing the profitability of your business.

6. Disrupted cargo delivery schedules: Issues with refrigeration unit operation can lead to disruptions in cargo delivery schedules, causing client dissatisfaction and risking contract losses.

Our solution, BCU-300:

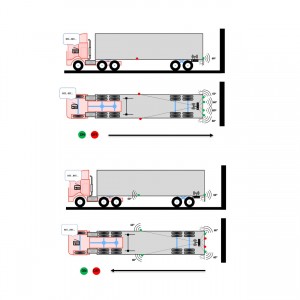

Installed in the refrigerated trailer's utility compartment, the BCU-300 unit operates with a 24V power supply from the truck's factory EBS socket. Upon connecting the semi-trailer to the truck, the unit immediately delivers the optimal voltage and charging current directly to the 12V aggregate battery.

1) Installation on the semi-trailer takes approximately 1 hour.

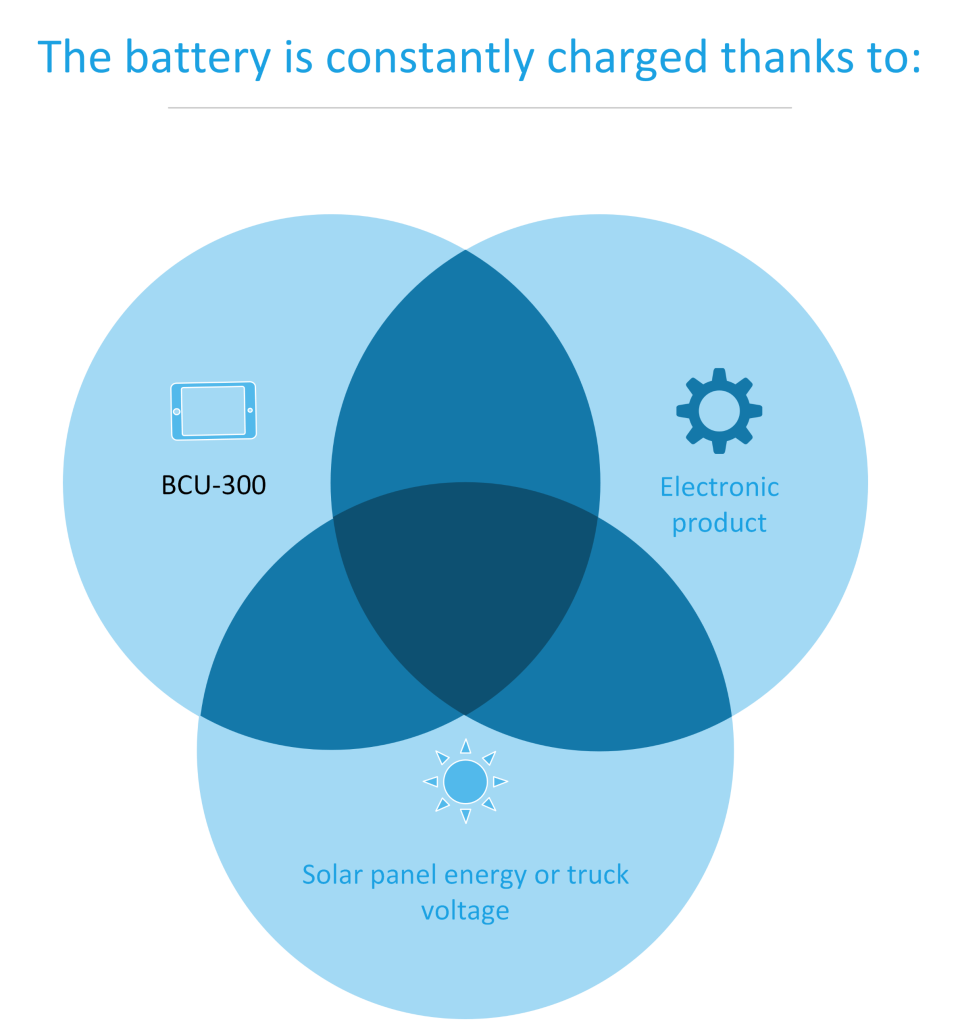

2) It provides the ideal charging voltage for the aggregate battery from the truck or a solar panel*.

3) No additional maintenance or staff training is required after installation.

Here's how it works:

1. Constant Analysis and Selection of Power Source: The BCU-300 continuously monitors available power sources, such as the truck or a solar panel*, and selects the optimal source depending on the conditions.

2. Optimal Voltage and Battery Charging Current: The BCU-300 regulates the voltage and charging current for both acid and gel batteries, ensuring efficient charging.

3. Monitoring Truck Battery Discharge: The device also keeps track of the truck's battery condition to prevent deep discharge, which could adversely affect the operation of the refrigerated unit and batteries.

Success Stories of Our Clients:

Example 1: After installing our unit and conducting test trials, cases of battery discharge were reduced by 80%. Downtime decreased by 25%. The company now plans to purchase BCU-300 units for its entire fleet.

Example 2: Following a demonstration of the BCU-300's at our showroom, the company acquired units for its entire vehicle fleet without further testing. Refrigerated trailer downtime was reduced by 20%. The technical director is satisfied with the results, and there have been no complaints from the drivers.

Example 3: Downtime decreased by 30%. Battery purchase expenses were reduced by a factor of 3. Fuel consumption for battery charging decreased by 80%."

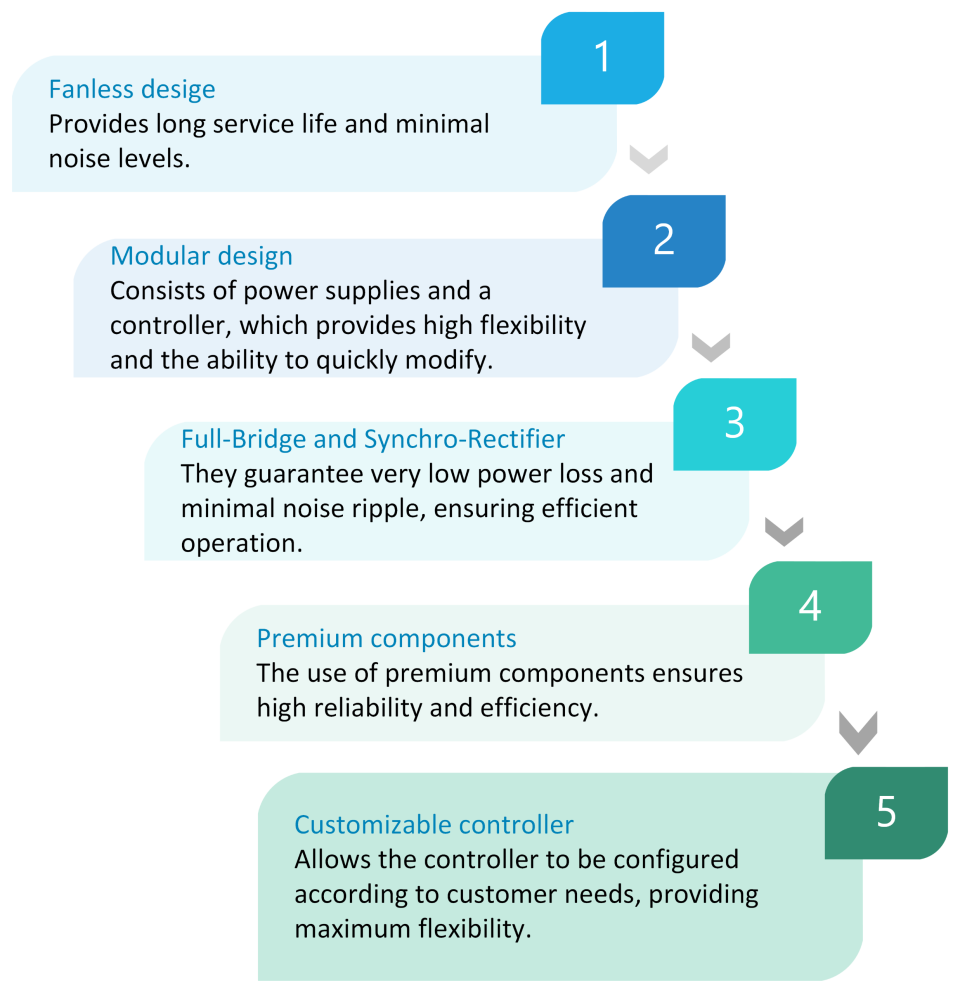

KEY FEATURES

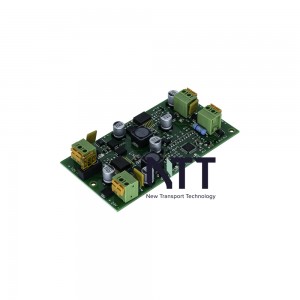

Main Parts of the Battery Charging Control Unit

Include a schematic diagram with numbers

1) BCU-300 main block

Description: The BCU-300 main block serves as the central control unit in the battery charging management block (BCU-300) system. It contains complex circuits and interfaces that allow smooth communication between various components and facilitate precise control of battery charging, monitoring, and protection functions.

Purpose:

1. Optimization of the battery management process

2. Smart charging management

3. Protection against discharge

4. Monitoring and improvement of reliability

2) Connectors

Description: Designed specifically for forklifts, they are durable and ensure accurate and reliable connection with forklift cables, making them an integral part of the BCU-300 system.

Purpose: To ensure a reliable and efficient connection between the BCU-300 system, forklift battery, and solar panel for effective charging, discharge protection, and better system management.

Main features:

Input:

- Monitors voltage and current levels.

- Protection against overvoltage/undervoltage and overcurrent.

- Offers solar energy input monitoring.

Output:

- Ensures voltage and current monitoring.

- Incorporates overvoltage/overcurrent protection and limiters.

- Allows for adjustment of charging voltage and current through serial interface.

- Facilitates charging adjustment to match different battery types and temperatures.

- Includes BCU temperature monitoring and, if necessary, power reduction.

- Enables separate or parallel use of solar energy with forklift energy.

- Has a serial interface for comprehensive monitoring and control.

Technical Characteristics of the Battery Charging Control Block

| Nominal Input Voltage | 24V |

| Input Range, all output characteristics | 15–32 V DC |

| Input Range, four-step charger mode | 24–32 V DC |

| Input Range, defect-free | 0-36V DC |

| Input Ripple (mV at 20 MHz bandwidth, idle (I out = 0A) | < 0.5 mV |

| at I output 20A, U output 12V | < 26 mV |

| Low Voltage Alarm Setting* | 15 VDC |

| Current Consumption Idle (I, approximately) | 32 mA |

| Lower Input Control Value Delay* | 30 sec. |

| Recommended Fuse Input | 10A-T |

| Reverse Polarity Protection | Yes |

| Overvoltage Protection | Yes |

| Wire Size < 2m | 1 mm² / AWG17 |

| Wire Size > 2m | 1.5 mm² / AWG15 |

| Nominal Voltage* | 13.8 V DC |

| Adjustable Voltage* | 12–15 V DC |

| Output Voltage Regulator (optional) | 4.0–13.0 V DC |

| Stabilized | 2% at extreme temperatures, load, and input |

| Output Ripple (mV at 20 MHz bandwidth), idle (I out = 0A) | < 5 mV |

| at I output 20A, U output 12V | < 120 mV |

| Maximum Power | 300 W @ output = 12.0 V |

| Rated Power | 200 W at U output = 12.0 V |

| Idle Current Consumption (I, sec.) | 57 mA |

| Response Time to State Change | 5 sec. |

| Operating Environment Temperature | Guaranteed operation: -20°C to 60°C. |

| Storage Temperature | -25°C to 85°C |

| Operating Humidity | 95% maximum, non-condensing |

| Galvanic Isolation | Yes |

| Cooling System | Natural convection, no fan |

| Current Limit | Yes, i-max |

| Four-Step Battery Charging | Yes |

| Efficiency | 90% (at nominal input voltage, full load), typical; 92% peak. |

| No Load Consumption | Typical <60 mA |

| Communication | RS232, for parameter changes and data reading |

| Soft Start | Yes |

| Indication | 3 LEDs |

| Supported 12 V Battery Types | Lead-acid or gel (temperature sensor installation required) |

| Overcurrent | Limited by current sensing circuitry |

| Overheat | Limited power of temperature sensing circuitry |

| Dimmer Function | Yes |

| Alarm Contact | Yes |

| Communication | Bluetooth, for parameter changes and data reading |

| Input/Output Connectors | Cable assembly with 24-pin socket 211PC249S0023 |

| Dimensions (WxHxD), excluding cables | 130 x 140 x 34 mm (130 x 175 x 34 with straps) |

| Connector | Aptiv 24-pin waterproof (IP67), HCCPHPE24BKA90F |

| Mounting Holes (2 pcs.) | Diameter 7 mm |

| Weight (without strap) | 520 g / 1.2 pounds |

| Frame | Anodized aluminum |

| 10R | EMS Directive 89/336/EEC, amendments 92/31/EEC, 93/68/EEC |

| Safety: | 73/23/EEC, 93/68/EEC amendment. |

| Vehicle Directive | 95/54/EC |

| Transient Voltage Protection: | Complies with ISO 7637-2. |

| ESD Protection: | Complies with ISO10605, 14892, contact 8kV, discharge 15kV |

| Software for setting control values | Default settings: Low input voltage 15 V, Low input voltage 25 V, Normal input voltage 27 V, Input overvoltage 32 V, Low output voltage 10 V, Normal output voltage 13.8 V, Output overvoltage 32 V, Output overcurrent 10A. * Configurable using software. |

| Company Code | Quantity | Weight 1 pc. (kilograms) | Description |

|---|---|---|---|

| K-3879 | 1 | 0.520 | BCU-300 block with aluminum housing Wiring harness with connector |

| Wiring harness with connector | |||

| K-3880 | 1 | 0.380 | Wiring harness with connector without temp. sensor |

| K-5091 | 1 | 0.410 | Wiring harness with connectors for solar collector without temp. sensor Assembly kit |

| Assembly kit | |||

| K-3818 | 1 | 0.103 | Total weight of assembly kit |

| K-3783 | 1 | 0.001 | Fuse 10A |

| K-3184 | 1 | 0.001 | Fuse 20A |

| K-4081 | 2 | 0.023 | Fuse holder |

| K-5013 | 2 | 0.001 | Thermally shrinkable tube 10 cm |

| K-4053 | 10 | 0.001 | Plastic strap 200 mm. |

| K-3800 | 2 | 0.006 | Self-tapping screw 40 mm M4 with star drill |

| K-3124 | 2 | 0.008 | M6 30 mm hexagon screw |

| K-3887, 3888, 3890, 4671, 4752, 4956 | 2 | 0.003 | M6 bolt |

| K-4753, 4755, 4757 | 2 | 0.001 | M6 nut |

| K-0773 | 1 | 0.001 | Grounding contact (red) 8mm |

| K-0772 | 1 | 0.001 | Grounding contact (blue) 8mm |

| K-3802 | 1 | 0.001 | Grounding contact (red) 10mm |

| K-3803 | 1 | 0.001 | Grounding contact (blue) 10mm |

| K-4088 | 1 | 0.004 | Plastic bag 200*150mm |

| K-3739 | 1 | 0.110 | Cardboard box |

| Opportunities | |||

| K-5092 | 1 | Temperature sensor with housing and 3 m long cable | |

| K-4636 | 1 | Solar battery |

Battery charging management block complies with TAPA TSR (Transported Asset Protection Association Trucking Security Requirements) guidelines, contributing to overall cargo security and safety. Specifically, it enhances compliance with TAPA TSR guidelines in the following ways:

1. Asset Protection: The battery charging management block ensures continuous operation of key trailer security and tracking systems. By preventing battery discharge during transit or extended periods of inactivity, it ensures the integrity and functionality of these security systems, which are essential components of TAPA TSR compliance.

2. Reduced Downtime: By reducing the risk of battery-related failures and malfunctions, the device helps minimize downtime during transportation operations. This aligns with TAPA TSR's focus on operational efficiency and uninterrupted flow of goods.

3. Environmental Considerations: The battery charging management block contributes to responsible resource and energy management. By extending battery life, the need for battery replacement is reduced, aligning with TAPA TSR's commitment to sustainability and reducing the environmental impact of logistics operations.

4. Remote Monitoring: Some versions of the device offer remote monitoring capabilities, allowing logistics operators to be informed about the battery status and actively address issues, even when the trailer is in transit. This is in line with TAPA TSR's emphasis on real-time monitoring and surveillance.

| Thumb | File information |

|

|

BCU300-PINOUT-ENG.pdf File Size177.81KB Downloaded: 0 |

|

|

BCU300 PINOUT RUS.pdf File Size202.41KB Downloaded: 0 |

|

|

BCU-300 Installation ENG.pdf File Size1.41MB Downloaded: 0 |

|

|

BCU-300 Installation RUS.pdf File Size1.55MB Downloaded: 0 |

|

|

LED-indication-ENG.pdf File Size114.36KB Downloaded: 0 |

|

|

BCU-300 Installation LT.pdf File Size1.42MB Downloaded: 0 |

|

|

LED indication rus.pdf File Size114.38KB Downloaded: 0 |

|

|

BCU-300 Installation Thermo King Krone Carrier LT.pdf File Size27.2MB Downloaded: 0 |