Trailer Electronic Door Lock

- Stock status: In Stock

- Model: DSM V2.0

- Shipping Weight: 11.00kg

- Dimensions: 20.00cm x 20.00cm x 5.00cm

- SKU: DSM V2.0

- MPN: DSM V2.0

NTT Trailer Electronic Door Lock

NTT introduces SmartLock PRO – an innovative solution tailored for freight carriers transporting high-value goods that require strict compliance with TAPA cargo security standards. This most advanced product is specially designed to meet unique requirements related to the protection of valuable cargo during transportation.

The SmartLock PRO DSM v2.0 door lock is a universal solution suitable for all types of trailers. This stainless steel lock can be conveniently operated remotely via a telemetry system or a variable code keypad. It securely attaches to the trailer doors, and unlocking and door opening data are smoothly transmitted to the office through the transportation management system installed in the front of the trailer. The electronic control module of the lock immediately sends notifications to designated individuals about any unauthorized opening. Rest assured, this electronic lock fully complies with the TAPA cargo security regulations and meets the requirements set by insurance companies. Developed and manufactured by qualified NTT engineers, the SmartLock PRO offers exceptional reliability and can be customized to specific needs of different carriers.

Additionally, you can enhance security measures by acquiring the SmartLock PRO S electronic door lock, which is an additional part of the safety package including alarms and various sensors. This comprehensive solution provides increased protection for your valuable cargo, ensuring peace of mind and security during transport.

Key Features

TAPA TSR Certification

The NTT electronic lock is designed to meet strict standards required to obtain the TAPA TSR certification. With the increasing prevalence of cargo thefts and loss of high-value and pharmaceutical goods, transportation rules have become more stringent. Obtaining the TAPA certification demonstrates that your supply chain adheres to appropriate security protocols, ensuring the protection and safety of your valuable goods throughout the transportation process.

Real-Life Tested

The SmartLock PRO electronic door lock for truck trailers has been thoroughly and rigorously tested in real-world scenarios, enduring the toughest conditions for an extended period. These tests included installing locks on trailers traveling through hot African regions, enduring the harshest Scandinavian conditions, operating in constantly rainy European locations, and facing frequent freezing in Scandinavian countries. These realistic tests provided invaluable insights into improving lock construction, ensuring that transportation companies can rely on exceptionally reliable equipment performance.

Electric Door Lock Specifications

| Material | Stainless steel AISI304 |

| Material Thickness | Body 3mm, bolts 15mm |

| Finish Type | Laser welding |

| Mounting Material | 6xISO8677, 2xISO7045 screws, 6xISO7093 washers, 8xISO10511 fixing washers |

| Lock Status Sensor* (open / closed) | Reed switch (NO) |

| Lock Integrity Sensor* (loop sensor) | Loop (NC) |

| Operating Temperature | -40-+80°C |

| Operating Humidity | IP65 |

| Mounting Options | body bolt attachment, bolt welding |

| Opening/closing time, avg | 3 sec |

| Dimensions, WxDxH | 225x210x55mm |

| Weight | 11 kg |

| Ingress Protection Rating | IPW66 |

| Gear (screw) travel length, max | 30-50 mm (adjustable during calibration) |

| Supply Voltage Range | 10-16V |

| Overvoltage Protection | yes, electronic, self-resetting |

| Overvoltage Protection, maximum holding | 70V |

| Supply Current, active | < 2A |

| Supply Current, standby | < 15mA |

| Supply Current, sleep | < 5mA |

| Overcurrent Protection | yes, electronics and fuse |

| Ingress Protection Rating | IP69 |

| Digital Inputs | 2 |

| Digital Inputs, levels | Low <2V; High>3V |

| Gear Control | with position and current monitoring |

| Keyboard Interface | serial |

| External Emergency Power Connection | yes, from the keyboard side |

| RS232 | optional |

| CAN | optional |

| Bluetooth | optional |

| RS485 | yes |

| Encryption | yes |

| LED Indicator | yes |

| Sound Signal: key press confirmation, alarm | yes |

| Operating Humidity | 5-95% |

| Operating Temperature | -40 °C to +85 °C |

Main Electronic Door Lock Components

- Door Lock with Locking Loop

- Left Door Locking Plate made of 10mm steel

- Right Door Locking Plate made of 10mm steel

- Mounting Hardware

- Lock Control Panel

- Gear

1) Door Lock with Locking Loop

Description: The door lock consists of a sturdy and durable body made of stainless steel AISI304 to withstand tampering, cutting, and harsh environmental conditions. It has a compact and ergonomic design, allowing for easy installation and operation.

Purpose: Designed to ensure reliable and secure door fixation, ensuring reliable closure and preventing unauthorized access to the semi-trailer cargo space.

Mounting materials: Stainless steel fastening details included.

Advantages: Stainless steel is resistant to mechanical damage, protecting structures from rust throughout its service life. The quality of the lock is not affected by weather conditions (see real examples).

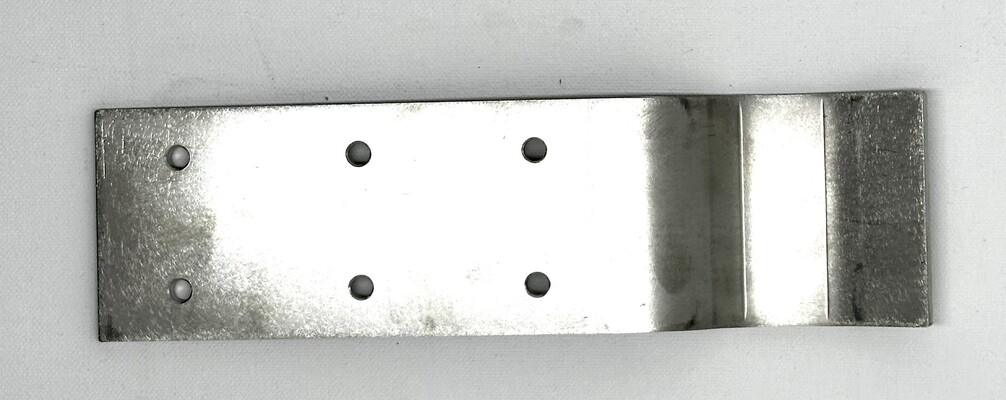

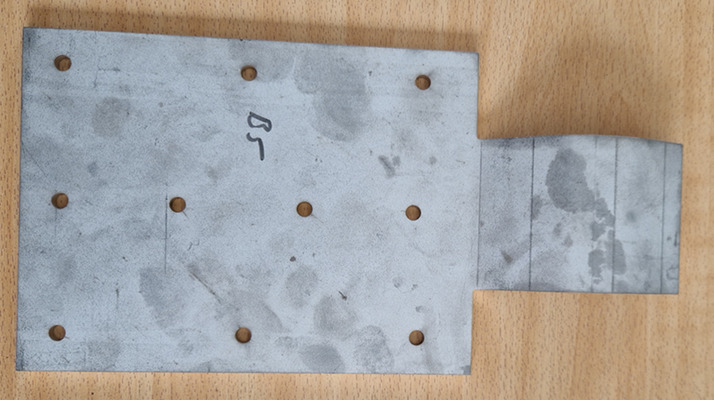

2) Left Door Lock Plate Made of 10mm Steel

Description: Attached to the left doors using existing fastening points intended for the door opening handle, eliminating the need for any additional perforations.

Purpose: To reinforce the left door security measures to prevent unauthorized access.

Mounting materials: Stainless steel fastening details included.

Advantages: The lock plate, made of solid 10mm steel, is characterized by exceptional durability and flexibility, ensuring a significant deterrent against unauthorized access. Its substantial thickness contributes to greater structural integrity, effectively reinforcing security measures for long-term protection.

Possibility to mount a 5mm stainless steel left door lock plate (various sizes available upon request).

3) Right door locking plate made of 10 mm steel

Description: Mounted on the right doors using existing fastening points for the door opening handle, eliminating the need for additional holes to be drilled in the doors

Purpose: Strengthen the structural integrity of the left door locking plate

Mounting materials: Stainless steel fastening details provided

Advantages: Made of solid 10 mm steel, it exhibits increased resistance, ensuring significant resistance to tampering and unauthorized access. Its steel composition not only guarantees longevity but also boasts excellent corrosion resistance, thus extending service life

Possibility to install 5 mm stainless steel right door locking plate (various sizes available upon request)

made of 10 mm steel (K-4653)

Right door locking plate (installed)

5 mm stainless steel

4) Fastening details

Description: Mechanical door lock fastening details are specially designed for use on semitrailers. Made of high-quality stainless steel, ensuring reliability, longevity, and corrosion resistance.

Purpose: The purpose of these fastening details is to securely attach the mechanical door lock to semitrailers. The use of stainless steel as a material ensures resistance to moisture, aggressive environments, and changing weather conditions, thus ensuring long service life and reliable operation of important semitrailer components.

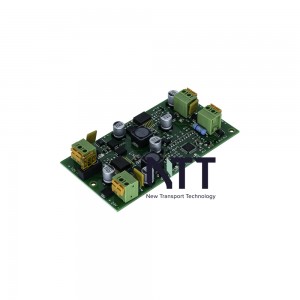

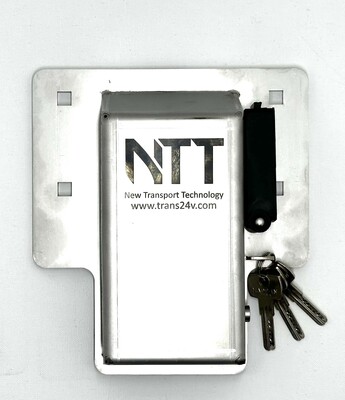

5) Lock Control Panel (Main)

Description: The keyboard integrated into the Electronical Door Locking System offers an intuitive user interface with LED indicators for clear visual status updates. Complemented by a responsive buzzer, it ensures both visual and auditory feedback for seamless interaction. Its ergonomic layout and remote management capabilities enhance user convenience and security.

Purpose: By adhering to TAPA standards, the keyboard enhances security protocols. It ensures that only authorized individuals, such as the driver, can unlock the door by inputting the PIN, thus fortifying the overall security of the system.

Description: The gear, a key component of the electronic door lock, is a mechanical powerhouse responsible for converting electronic commands into physical motion. Precision-engineered, it engages the lock mechanism to facilitate easier and secure locking and unlocking of doors.

Purpose: The main purpose of the gear is to ensure reliable and controlled transition of the electronic door lock system between locked and unlocked states. Responsively reacting to electronic inputs, such as PIN verifications, it ensures authorized access while adhering to system security protocols, thus safeguarding trailer contents and enhancing overall operational efficiency.

Additionally:

- Possibility to install lock position sensor

- Possibility to install lock tamper sensor

- Possibility to install 5 mm stainless steel right and left door locking plates

- Possibility to install 10mm steel right and left door locking plates

- Possibility to install only left door locking plate made of 5 mm stainless steel

- Tailored product adaptation is available for use on various types of trailers, including REEFER, BOX, and CURTAINSIDER configurations. Additionally, we are prepared to customize additional adaptations according to specific requirements and preferences of our esteemed customers

We design and promptly implement changes to meet specific needs of our customers upon request

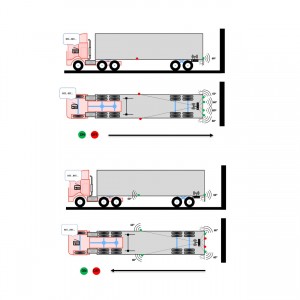

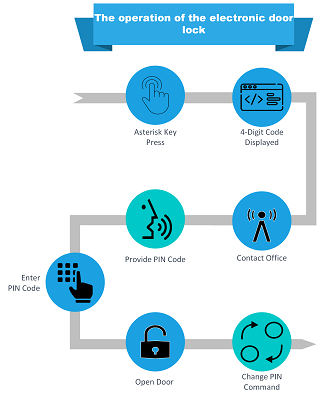

The operation process of the electronic lock can be divided into the following steps:

1. When a driver takes responsibility for or hands over a trailer, they initiate the process by pressing the (*) button on the lock keypad.

2. Upon pressing the (*) button, the keypad displays a 4-digit code. This code is unique to the current session.

3. The driver contacts responsible personnel at the office and communicates the 4-digit code displayed on the keypad.

4. Upon receiving the code from the driver, office staff generate and provide the corresponding PIN code for lock unlocking and locking.

5. The assigned PIN code remains unchanged until responsible office personnel send the "Change PIN" command to the lock.

6. If necessary, responsible office personnel can remotely send the "Change PIN" command to the lock from the office.

7. Upon receiving the "Change PIN" command, the driver, especially a new driver, must contact the office again to obtain a new PIN code displayed on the keypad screen.

If the driver enters an incorrect PIN code, the keypad displays an "Err4" error message, indicating that the input was incorrect.

Responsible office personnel have a PIN code generator, which generates PIN codes for unlocking based on driver requests and specific protocols. This generator ensures secure access control and authentication with respect to the lock.

There are three ways to change the electronic lock password:

1) Constant password: This password remains constant forever and never changes.

2) Password change when a responsible person changes it in the office (e.g., when a new driver comes to inspect the semi-trailer). In this case, the password is changed only when the responsible person in the office decides to change it.

3) Password changes constantly after lock opening and closing. Every time the trailer is opened, you need to contact the office and get a new password. This scheme ensures that each time the semi-trailer is opened, the password is unique, and the driver must contact the office to get a new password.

Key operating principles

The smart lock system operates according to three different user classifications, each assigned special permissions: driver, installer, and master (most advanced role).

- Driver: This role grants the ability to perform actions such as opening-closing, emergency opening-closing, enabling and disabling automatic closing.

- Installer: Users assigned as installers can manage device parameter configuration, calibration, block association, reset driver password, and change configuration password.

- Master: The "Master" designation provides access to opening-closing functions, block association, the ability to change installation program password, and the ability to change the master password.

The design philosophy revolves around hierarchical control, where higher-level users have permissions to control functions accessible to lower-level users.

| Company Code | Description |

Smart Lock Main with Alarm | |

| 4315 | Main Board "Smart Lock". |

| 4251 | Plastic Box SCAME - Panel IP66 |

| 2940, 4081 | 5A Fuse 0452005.MRL+ Fuse Holder MTA-UNI-HOLDER |

| Cable 3-wire 2 m | |

| 4536 | Siren Ampire 514F 12V |

| 4954, 4955 | Magnetic Contact Glue MKL102S |

| 205 | Plastic Gland - Seal M12 D3-6.5 mm IP68 gray (x2) |

| Smart Lock Act | |

| 4996 | Assembled Board Lock_Combo_Emer_v3 |

| 4997 | Assembled Board Lock_Combo_Act_v3 |

| 2657 | Box Z96JH-PS (50x70x36) mm gray |

| 3865 | AMP Connector, 3-pin male-female (x3) |

| 4950 | AMP Connector 2-pin male-female |

| 2789 | Reed switch KMS-25(KMS-31) - Herkon |

| 2934 | Plastic Gland PG9 - Cable Seal PG9 IP68 gray |

| Assembly Kit | |

| 0461 | Plastic Tube D.8 1.2mm |

| 0717 | Metal Clamps - Clamps with pl. plastic tube |

| 3162 | Brackets 66cm - (PVC cable channel 50mm, gray (2m)) |

| 1743 | 3-core cable 20m - (Cable H03VV-F 3x0.5 black) |

| Plates | |

| K-4652 | Plate B2 reinforced iron |

| K-4653 | Plate B3 flat iron |

| K-4654 | Loop B4 for lock set |

| K-4656 | Plastic spacer |

| K-4267 | Lock AL-S840 |

| K-4674 | Rubber lock holder |

| K-4031, K-P847 | Lock preparation works |

| K-4490, K-4441 | Screws 10 x110 |

| K-4488, K-4256 | Screw 10x110 fully threaded furniture |

| K-4491, K-2855, K-2856 | Bolt with plastic M10 |

| K-4647, K-2854 | Large washer 10.5x30 |

| K-4489, K-2936 | Small washer 10.5 |

| K-4442 | Receiver 82 mm (Aluminum tube d.13x1.0mm) |

| Receiver 79 mm painted (Aluminum tube d.13x1.0mm) | |

| K-4334 | Fixing ring |

TAPA CERTIFICATION

The SmartLock PRO electronic door lock complies with the TAPA TSR-1 criteria as follows:

9.11.1 - High-Quality Locking Device: The SmartLock PRO DSM v2.0 door lock is made of high-quality stainless steel, meeting the criteria for being constructed from stainless or hardened steel. It is a heavy-weight high-security locking device permanently installed on cargo compartment doors, which aligns with the requirement of not using temporary devices such as chains, cables, light-weight bars, removable bolts, or brackets. The lock is securely mounted on the door of the semi-trailer and is designed for permanent use throughout the entire journey.

9.11.3 - Lock Features:

Electronically Operated: The SmartLock PRO can be controlled electronically through a telemetry system or a variable code keypad. It offers the option for both automatic and manual operation, meeting the requirement of electronic, automatic, or manual operation.

Unique Locks: The lock provides a variable code keypad, ensuring unique codes for access. Duplicated codes/keys/passwords to open different locks are not permitted, which complies with the uniqueness requirement.

Tamper Evident and Withstands Substantial Force: The lock is designed to withstand substantial force and is tamper-evident. It promptly sends notifications in the event of any unauthorized opening, which aligns with the requirement for locks and fixing devices to withstand force and be tamper-evident.

VIDEO INSTRUCTION

| Thumb | File information |

|

|

Smart Lock Pro Installation ENG.pdf File Size2.02MB Downloaded: 0 |

|

|

Smart Lock Pro Installation RUS.pdf File Size2.1MB Downloaded: 0 |

|

|

Smart Lock Installation LT .pdf File Size2.06MB Downloaded: 0 |

|

|

Smart Lock PRO PINOUT LT.pdf File Size524.51KB Downloaded: 0 |

|

|

Smart Lock PRO PINOUT ENG.pdf File Size523.08KB Downloaded: 0 |

|

|

Smart Lock PRO PINOUT RUS.pdf File Size609.42KB Downloaded: 0 |

|

|

Emergency Lock Opening ENG.pdf File Size8.85KB Downloaded: 0 |

|

|

Emergency Lock Opening RUS.pdf File Size39KB Downloaded: 0 |

|

|

User manual Smart Lock PRO ENG.pdf File Size409.72KB Downloaded: 0 |

|

|

User manual Smart Lock PRO RUS.pdf File Size522.73KB Downloaded: 0 |

|

|

SmartLock Pro S brochure RUS.pdf File Size529.81KB Downloaded: 16 |

|

|

SmartLock Pro S brochure ENG.pdf File Size442.36KB Downloaded: 16 |

|

|

SmartLock Pro S brochure LT.pdf File Size520.09KB Downloaded: 14 |